-

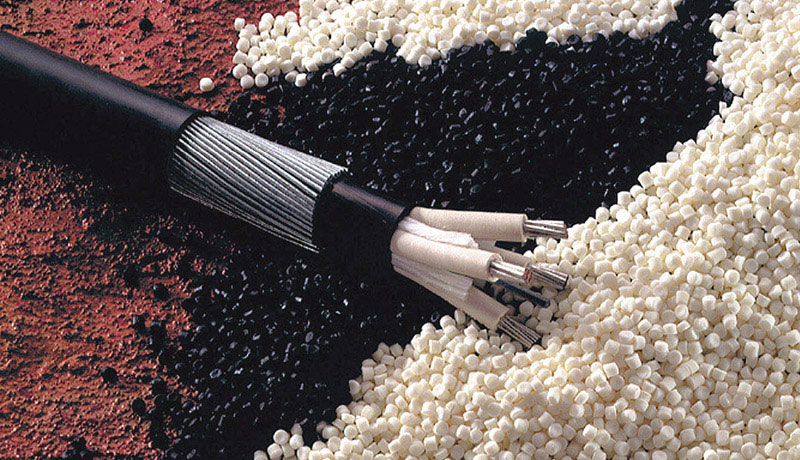

Conductive carbon black requirements for cable shielding.

Requirements for conductive carbon black used in shielding materials for cables, both internally and externally, include low electrical resistivity, high dispersibility, small particle size, large and rough specific surface area, high structure, and clean surface (low compound content).

-

What is the difference in conductivity between superconducting carbon black and highly conductive carbon black

The difference in conductivity between superconducting carbon black and highly conductive carbon black is not significant, mainly due to differences in application fields. Superconducting carbon black is commonly used in plastics, while highly conductive carbon black is commonly used in rubber.

-

Industrial carbon black is an indispensable chemical raw material in industry

Industrial carbon black is an indispensable chemical raw material in industry. Its dyeing and reinforcement properties make it a modification additive for most plastic and rubber products, with tire usage accounting for more than 70% of the total.

-

How to choose conductive carbon black? Superconductive conductive carbon black, acetylene carbon black

How to choose conductive carbon black: For conductive carbon black, it is necessary to choose one with good conductivity, such as superconducting carbon black, acetylene carbon black, etc. Choose according to the characteristics and requirements of the product. Suitable carbon black varieties can be selected, such as ultra wear-resistant medium wear-resistant, high wear-resistant furnace black, etc., which can endow the tread with excellent wear resistance

-

What raw material is conductive carbon black made from? What are the production processes for conductive carbon black?

There are currently two processes for conductive carbon black in the market. One is manufactured using acetylene gas, which has extremely high electricity costs and excellent conductivity. It is mainly used in the battery industry. Another type of conductive carbon black produced by heavy oil pyrolysis process or fertilizer plant exhaust gas, with ultra-high specific surface area and ultra-high conductivity, is mainly used in the rubber and cable industries.

-

The conductivity of conductive carbon black is endowed and determined by the microstructure of carbon black

The conductivity of conductive carbon black is endowed and determined by the microstructure of carbon black, so the conductivity of conductive carbon black is directly related to its structure. How to determine the conductivity of conductive carbon black specifically? Here are a few practical methods provided for everyone.

|